Polymers and Plastics are inherent insulators in nature and thus when subjected to triboelectric environments can accumulate electrostatic charge on their surfaces. This happens when polymers are subject to friction with other materials of similar or dissimilar nature (for eg. metals) or their separation from other surfaces. When the charged polymer surface comes in contact with a neutral or oppositely charged surface (including humans) there is a possibility of spontaneous electrostatic discharge.

This spontaneous electrostatic discharge is undesirable due to various reasons:

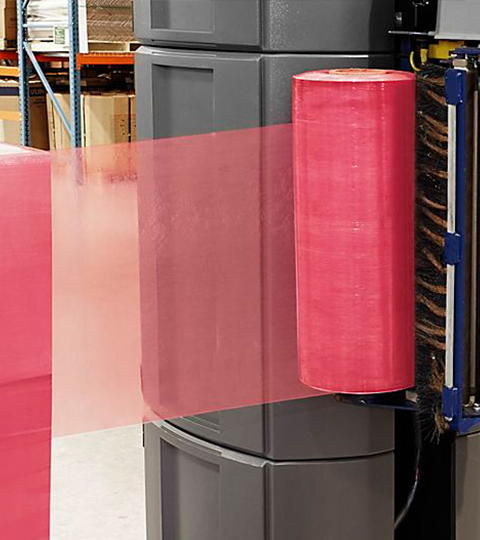

It can cause constraints in handling and processing of plastics including post processing, conveying, packing, storage and transport

Leads to undesirable accumulation of dust, dirt and other contaminants on plastics surfaces which reduces aesthetics, hampers end use functionality (eg. sealing ability, paintability), increased rejects in critical applications like food and medical packaging

Can damage sensitive circuits in electrical and electronics components, military hardware, medical equipment, PLCs and microelectronics of ancillary processing equipment at the plant

Pose significant fire and explosion hazard in the vicinity of flammable materials such as solvents or explosive dusts and gases

Unwelcomed electric shocks to operators on the shop floor with possibility of critical accidents in extreme cases

Anti Static masterbatches are added to address above challenges. Most regular anti stats are incompatible with polymers and thus migrate to the surface and form a hydrophilic layer which enables the safe discharge of accumulated static charge. This mechanism is dependent on ambient relative humidity levels.

A range of anti static masterbatches can be offered depending upon the expected service life and level of surface resistivity reduction desired (usually resistivity of 109 Ohm/ Sq is achievable with regular antistats, we are working for 108 Ohm/Sq) , relative humidity levels during use, regulatory requirements eg. food approvals and criticality in post processing such as surface printing and treatment.