1. Automotive parts: Masterbatch can be added to the polymer during the manufacturing process to create automotive parts that are made of recycled Polymer, have improved strength, or have enhanced color.

2. Household goods: Masterbatch can be used to create household goods such as plastic containers, toys, and small appliances that are UV resistant, have improved strength, or have enhanced color.

3. Medical devices: Masterbatch can be used to create medical devices such as syringes and tubing that are UV resistant, have improved strength, or have enhanced color.

4. Industrial components: Masterbatch can be added to the polymer during the manufacturing process to create industrial components that are UV resistant, have improved strength, or have enhanced color.

5. Packaging components: Masterbatch can be used to create packaging components such as caps and closures that are UV resistant, have improved strength, or have enhanced color.

6. Electrical parts: Masterbatch can be added to the polymer during the manufacturing process to create electrical parts that are UV resistant, have improved strength, or have enhanced color.

Overall, the use of masterbatch in the injection molding process allows for the customization of the final product for specific applications and can lead to improved performance and aesthetics of the final moulded product.

Mulch Films to reduce weed growth, evaporative water losses, need for pesticides, fertilizer and irrigation , whilst also enhancing plant growth.

Silage Films to aid fermentation of biomass for animal fodder & avoid the need for huge set up for storage.

Tunnel & Green house films to protect & enhance plant growth, extend cropping seasons, thereby increasing yields.

Shade nets to protect the crops from excessive sunlight, insects, birds and extreme wind.

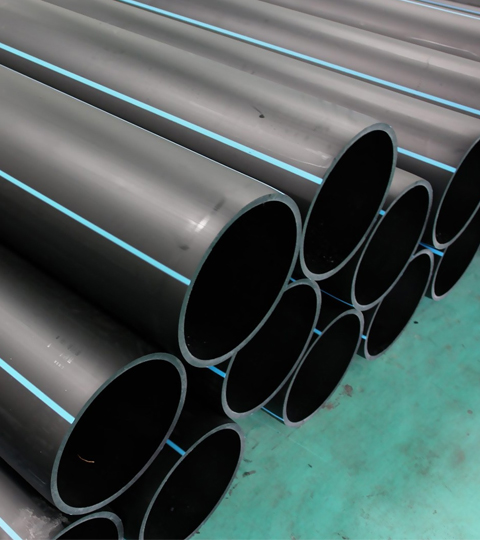

Drip pipes & sprinklers for effective water usage by allowing precise water application, minimum evaporation & reduced run off.